|

Fisher

Body - Home

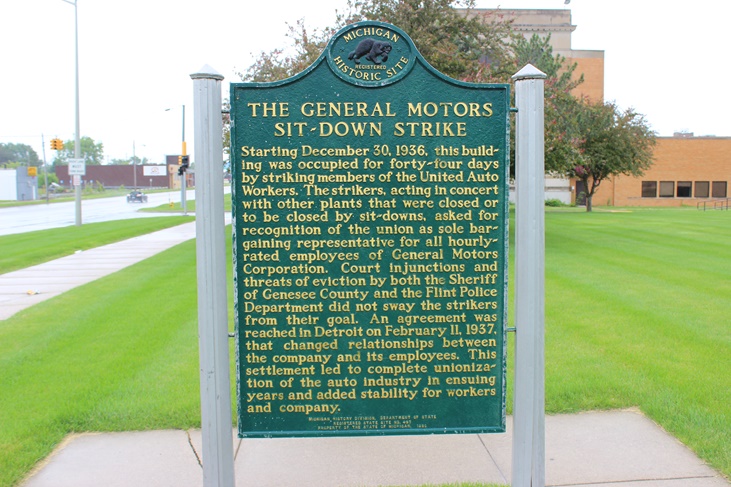

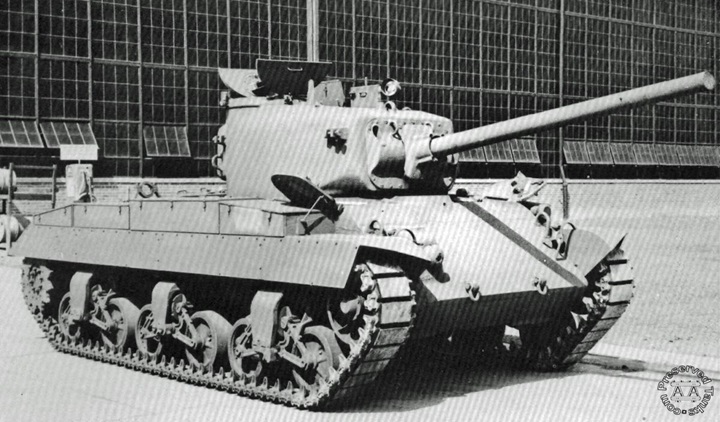

Grand Blanc Tank Arsenal Built Tanks and Tank Destroyers The Fisher Body Flint, MI Plant #1 in World War Two Author's note: Seventy-three years after the end of World War Two, and eighty-one years after the end of the 1936-37 sit-down strike at Fisher Body #1, I looked back at events during the tumultuous years from 1936 to 1945; and have reviewed what happened at the plant with a new and different prospective. To a large extent, the Flint Fisher Body #1's (Flint #1) contribution to the winning of World War Two has been overshadowed by the more well known Grand Blanc Tank Arsenal, 4.5 miles south of Fisher Body #1. My investigation shows that the two plants worked very closely together to produce the 19,034 armored fighting vehicles that were produced that came off the assembly lines of the Fisher Body Grand Blanc Tank Arsenal. The American Automobile Industry's Unrecognized Sherman Tank Plant - Fisher Body Flint Plant #1: In April1942, M4A2(75)VVSS Serial Number 2305 and Registration Number 3014311 came off the improvised assembly line at Flint Fisher Body Plant #1. Serial number 2305 then made the 4.5-mile trip down Saginaw Street to the Grand Blanc Tank Arsenal, still under construction, to use its newly built test track. Flint Fisher Body #1 built the first twenty Sherman tanks produced by the Fisher Body Division of General Motors. This fact has been overlooked. When recognized by Sherman tank historians, the twenty M4A2s are included in Grand Blanc's production numbers. I disagree with this. Flint #1 was its own entity and needs to be recognized as a tank plant in its own right. The following quote is from page 24 of Fisher Body's war history, "Fisher Body Craftsmanship Goes to War." "Actual production was started in January 1942 in a converted section of Fisher Body's large plant in Flint, Michigan, sixteen days before the last automobile body was completed. The first M-4 came off the line under its power just 47 days after work was started, and a new tank was born." The article goes on to state that the Grand Blanc Tank Arsenal was being constructed, and that final assembly of the Sherman tanks moved to that location when it was completed.

That brings up the question of how many

M4A2s did Flint #1 build, and when did production start at Grand Blanc?

Information from page 359 of "The Sherman - Design and Development"

(Better known as "Son of Sherman - Volume 1.") by Patrick Stansell and

Kurt Laughlin provides clues. It shows Grand Blanc building four

M4A2s in April, and sixteen in May 1942. The authors state on page

18 that Grand Blanc started production in July 1942. This is

incorrect. They probably meant to say June. Flint #1 was not

equipped to turn out 177 Sherman tanks in one month. They note

that tanks had been previously built at a Fisher Body plant in Flint,

which would be Flint #1. The authors identify Fisher Body as a subsidiary of General Motors.

This is also incorrect. It was a division of GM. At the time of

World War Two, it was the largest division within GM, even larger than

Chevrolet. How Grand

Blanc was able to produce so many tanks its first month in production

will be addressed later on this page. The takeaway at this point

is that the first 20 Sherman tanks built by Fisher Body Division were

built in Flint #1. This is the most historically significant of all of the Fisher Body Plants but all of the auto plants, if not all US auto plants, because it was here during a sit-down the 1936-37 strike which caused General Motors to recognize the UAW. The plant, with the exception of this historic building, was torn down in 1988.

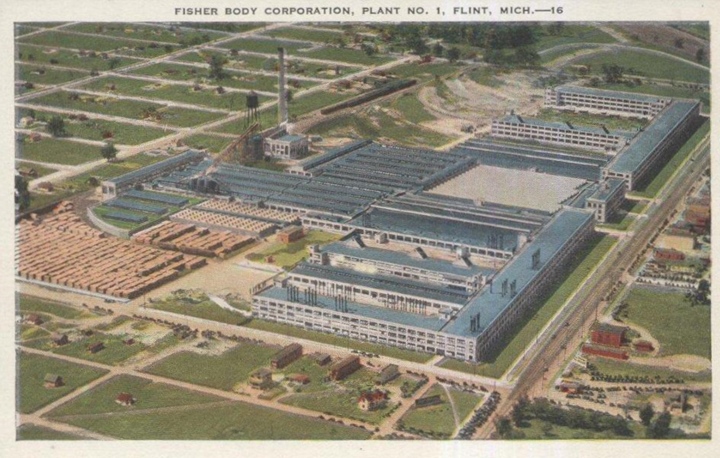

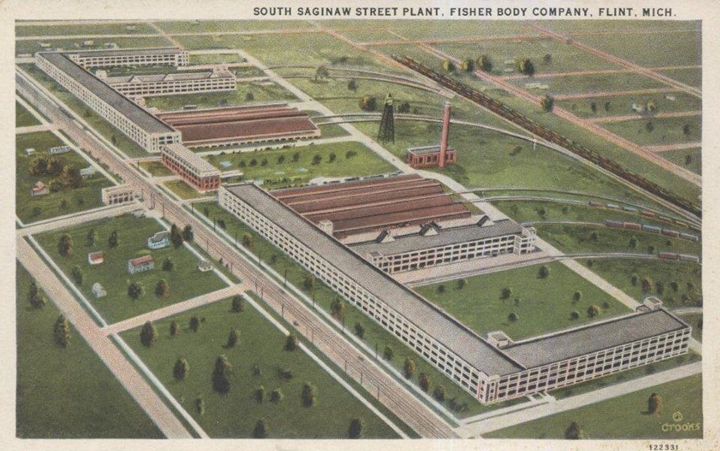

Built in the 1920s, this building was originally the headquarters for Durant Motors. General Motors bought this building and the former Durant Motors automotive assembly plant in 1926 for $4 million. As part of Fisher Body, it produced bodies for the Buick plant on the north side of Flint. Author's photo.

World War Two:

Fisher Body Flint Plant #1 was awarded the

Army-Navy "E" Award five times during World War Two. Fisher Body Flint #1 World War Two Products: M4, M10, M26, M36, M18 Tank Parts and Tank pilot models and parts. M4, M10 Experimental Models. Tank Tools and fixtures. 120mm and 155mm Gun Parts, 5-inch Naval Gun parts, B-29 and XP-75 Aircraft fixtures. Author's note on the importance of Flint Fisher Body #1 in World War Two: The World War Two history of Flint Fisher Body is intertwined and overshadowed by the Fisher Body Grand Blanc Tank Arsenal 4.5 miles south on Saginaw Street. The 19,014 tanks, tank destroyers, and prime movers it built are better documented than the work Flint #1 did to make the building of those armored fighting vehicles possible. What was lost after the war was the knowledge that Flint #1 was an extension of Grand Blanc, and vice versa. Grand Blanc was a high output plant where the prime goal was to assemble tanks and tank destroyers as quickly as possible for the U.S. Army. Flint #1 developed the tooling and fixtures, and then tested them before shipping them to Grand Blanc where they were installed and brought up to line speed with a minimum of lost time. Many of the prototypes for the changes and new tanks and tank destroyers produced at Grand Blanc were built and tested at Flint #1. High volume production of any product involves making tooling and fixtures ahead of time. This is what Flint #1 did. It was Grand Blanc's main tool room and engineering center. M4 Series Sherman tank:

In June 1942 the Grand Blanc Tank Arsenal produced 177 M4A2 Sherman tanks. It could never have produced that many in its first month of production without the lessons learned from the first 20 produced at Fisher #1 in April and May 1942. There were many changes to the various models of the 11,338 M4 Sherman tanks produced by the Grand Blanc tank arsenal during WWII. Sherman production started with the M4A2 small hatch with dry storage for the 75mm main gun ammunition. Later, an improved version of the M4A2 had larger hatches for the driver and assistant drivers, which totally changed the configuration of the front glacis and how it mounted to the side armor plates. Flint #1 redesigned and made tooling and weld fixtures, and then tested them on prototype parts before the tooling and fixtures were shipped to Grand Blanc for installation. Flint #1 also did the same thing for them when the M4A2 was modified internally for wet 75mm ammunition storage. When the M4A2 was converted to a 76mm main gun, Flint #1 developed tooling for machining the newer, larger turret. In February 1944 Grand Blanc started production of the large hatch M4A3(75). While similar to the M4A2(75) it was already producing, the M4A3 had a different engine. Before production started, Flint #1 worked on reconfiguring the engine bay from having twin six-cylinder diesel engines to a single V-8 gasoline engine. All of the internal connections to the main tank had to be redone before the tank could be released for high speed production. Fisher Body #1 would have done the prototyping and built many of the tools and weldments for the following versions of the Sherman tanks built by Grand Blanc during the war. When production stopped in May 1945 on M4 series tanks at Grand Blanc, 1,100 workers were laid off at Flint Fisher Body Plant #1. These employees would have been making parts for the Sherman tank built at Grand Blanc.

M10 Wolverine tank destroyer development:

M26 Pershing tank development: In late 1944 production of the M26 Perishing heavy tank began at Grand Blanc. For several years there had been much development and several different prototypes built before the design release of the M26 Pershing. Fisher Body Flint #1 engineers worked with U.S. Army Ordnance on these various prototypes; The plant built the fixtures and tooling to produce two T20 tanks in May 1943, 40 T25E1 tanks from February to May 1944, and ten 26E1 heavy tanks also from February to May 1944. In the case of the two T20s, they may very well have been assembled at Flint #1 rather than interfere with the high production Grand Blanc lines.

Fisher Body Flint # 1 / Grand Blanc shared World War Two Products: The products listed below are in listed in "Fisher Body Craftsmanship Goes to War" tank section of the book. It does not specifically say whether Grand Blanc or Fisher Body Plant #1 did the work. Probably Grand Blanc did a lot of the large weldments as it was set up for that. But Fisher Body #1 did all of the development work, and probably did many of the small weldments and subassemblies. Tank and Tank Destroyer Components - Weld fixtures and tooling for (2,245) M18 turrets, (1,511) M18 hulls, the conversion of (600) older M18s into M39 prime movers, and the new construction of (40) new M39s. Fixtures for (487) M36 tank destroyers M18 Turrets and Hulls: Buick was the prime contractor for the M18 Hellcat tank destroyer. However, because it was aware that Fisher Body #1 on the south side of Flint and the Grand Blanc Tank Plant were more experienced in the fabrication of armored plate, it asked Fisher Body to build the tooling, weldments and many of the turrets and hulls. There was a total of 2,507 Hellcats made. Fisher Body built 90% of the turrets, and 60% of the hulls. Due to the fact that the armor plate was thinner on the M18 than the M10, (Which wasn't all that thick to begin with!) engineers at Fisher Body Flint #1 had to develop different methods of welding to prevent distortion. Heavy duty weldments had to be made to combat the problem.

M39 Prime Mover: Buick was also the prime contractor of this vehicle, but Fisher Body Flint #1 and Grand Blanc did all of the work. Fisher Body converted 600 previously used M18s to the M39 Prime Mover. Fisher Plant #1 did the design changes and built the necessary fixtures. Another 40 brand new M39s were built by Fisher Body.

M36 Turrets and Conversion of M4A3 M10, and M10A1 Hulls for 90mm ammunition: In November 1943 Fisher Body was authorized to build 300 M10A1 Wolverines without turrets. These would be converted to the new M36 tank destroyer with a 90mm main gun. The M10A1 hull interior had to be extensively redesigned by Flint #1 engineers to accommodate the larger 90mm ammunition. New weld fixtures and prototypes then had to be built by Fisher #1 to test to see if they fit properly. Fisher Plant #1 also designed a brand new hydraulically controlled turret for the larger 90mm main gun. A turret basket was added and an improvement in the electrical wiring. Enough fixturing had to be built not only for the M36s coming down the line at Fisher Body Grand Blanc, but also for another 719 turrets being supplied to other manufacturers converting the M10A1 into the M36. The same turret was applied to converting 187 M4A3 tanks taken off the line to make the M36B1. The M4A3 had to have the interior of the hull redesigned for the 90mm ammunition of the larger gun. Fisher Body #1 did the redesign of the interior, made the ammunition trays, and delivered them to the Grand Blanc Tank Arsenal so that the first prototype was completed in only five days.

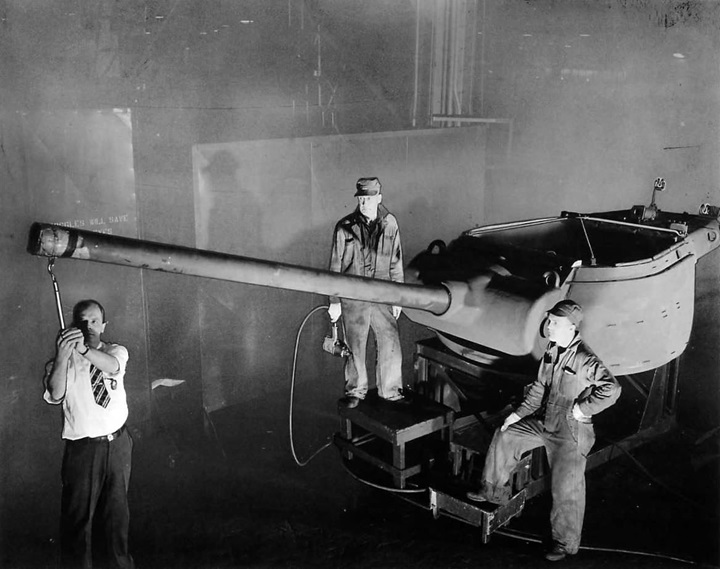

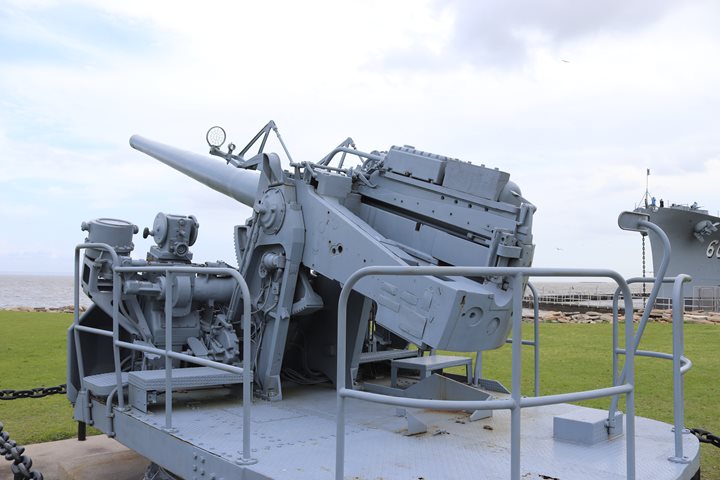

5-Inch, 38 Caliber Naval Gun parts: The Fisher Body Die and Machine Plant in Detroit, MI, and the Grand Rapids, MI Fisher Body plants produced 6,342 five-inch breech housing for five-inch naval guns during WWII. Flint #1 provided parts to these two plants for the five-inch guns.

120mm M1 Anti-Aircraft Gun parts: Fisher Body Grand Rapids was the sole producer of 550 120mm M1 Anti-Aircraft guns which entered service with the US Army in the Philippines in 1945. Flint Fisher Body #1 made parts for this weapon.

155mm "Long Tom" Gun parts: Flint Fisher Body #1 made parts for this weapon.

B-29 Jigs and Fixtures: Flint Fisher Body #1 built jigs and fixtures that were used for assembling the wings, wing flaps, stabilizers and nacelles. These fixtures were then sent to Fisher Body plants in Lansing, MI, Cleveland #1, OH, Cleveland #2, OH, Fleetwood in Detroit, MI, Pontiac, MI, Memphis, TN, and Grand Rapids, MI.

B-25 Jigs and Fixtures: As early as December 31. 1941 Flint Fisher Body #1 was making jigs and fixtures for B-25 components being assembled by the Fisher Body Plant in Memphis, TN. These components included wing sections, rudders, and vertical and horizontal stabilizers.

XP-75 Aircraft Jigs and Fixtures:

|